Do You Have A Project We Can Help With?

Over Pressure Vents

Over Pressure Vents are designed to allow pressure relief within a room during the discharge of a Fire Suppression Agent especially Inert Gas Fire Suppression Systems. This is because the amount of gas being added to the room could be up to 50% more than was there before. This creates an over pressure that must be vented to fresh air to ensure that the walls, windows or doors are not damaged during a discharge.

Although Over Pressure Vents have always been used in rooms where Inert Fire Suppression Agents such as INERGEN®, it is only recently that they have been recommended for use for FM200 and Novec 1230 (clean chemical agents).

The big question normally asked especially if the room being protected is in the middle of the building is can the Over Pressure Vent be vented to an adjacent room. Preferably the vent should either go straight to fresh air or ducted to fresh air. In the event this is not practical you can vent to an adjacent room as long as the adjacent room is 10x the volume of the room being protected. Remember that you cannot extract to an adjacent room only vent to it and only where it is not practical to vent to fresh air.

Inert Gas Over Pressure Vents

Inert Gas Over Pressure Vents have been part of the minimum requirements and local standards for many years (see BS EN 15004) but we have seen in many takeover’s of especially in older systems that they have either been supplied and not fitted or not supplied at all. As well as not complying with the relevant standards it is extremely dangerous as the pressures within a room during a discharge of the Inert Gas can be strong enough to damage suspended ceilings (especially if gas is not discharged into the ceiling void), walls, windows and doors. In fact it will go for the weakest point in the room, so it is imperative that Over Pressure Vents are fitted to all rooms containing Fire Suppression Agents such as INERGEN® , IG55, Argonite and IG541, if in doubt then please contact us.

Inert Gas Over Pressure Vents have been part of the minimum requirements and local standards for many years (see BS EN 15004) but we have seen in many takeover’s of especially in older systems that they have either been supplied and not fitted or not supplied at all. As well as not complying with the relevant standards it is extremely dangerous as the pressures within a room during a discharge of the Inert Gas can be strong enough to damage suspended ceilings (especially if gas is not discharged into the ceiling void), walls, windows and doors. In fact it will go for the weakest point in the room, so it is imperative that Over Pressure Vents are fitted to all rooms containing Fire Suppression Agents such as INERGEN® , IG55, Argonite and IG541, if in doubt then please contact us.

Clean Chemical Agents Dual Pressure Vents

The vents for clean chemical agents are different as the pressures exerted during a discharge are both positive and negative . This means that not only does the Pressure Vent have to operate to allow for positive pressure but also for negative pressure. The Pressure Vent has two vents within one enclosure, one allowing positive pressure to fresh air and a second vent that allows negative pressure to pull air from the outside. Although the pressures aren’t as great as Inert Gases we have seen rooms where a very well sealed room has damaged a block wall during a discharge! Although not part of the current standards it is a recommendation for Clean Chemical Suppression System installations such as FM200, FE-227 and Novec 1230.

The vents for clean chemical agents are different as the pressures exerted during a discharge are both positive and negative . This means that not only does the Pressure Vent have to operate to allow for positive pressure but also for negative pressure. The Pressure Vent has two vents within one enclosure, one allowing positive pressure to fresh air and a second vent that allows negative pressure to pull air from the outside. Although the pressures aren’t as great as Inert Gases we have seen rooms where a very well sealed room has damaged a block wall during a discharge! Although not part of the current standards it is a recommendation for Clean Chemical Suppression System installations such as FM200, FE-227 and Novec 1230.

How To Calculate the Size of a Pressure Vent

The information we need to be able to calculate the size of the vent is the room volume, type of Fire Suppression System (Inert Gas, FM200 or Novec 1230) and maximum allowable room pressure in pascals. The maximum allowable pressure in pascals is usually the hardest thing to get from any building designer or engineer as it is not normally calculated so we work on the basis of the following:

| Room Materials | Pressure (pascals) |

|---|---|

| Block | 250 |

| Timber | 500 |

| Glass | 100 |

Please note that these are not conclusive but at least provide some for of safety for the fabric of the room.

This information is then input into a Pressure Vent Calculator that will calculate what is termed the minimum Free Vent Area. This is the minimum area required to vent and this applies to the vent blades as well as the duct if fitted. Care must be taken in selecting the correct size of vent and multiple vents must be used if the largest vent is not big enough or multiple small vents need to be installed for aesthetics or practicalities.

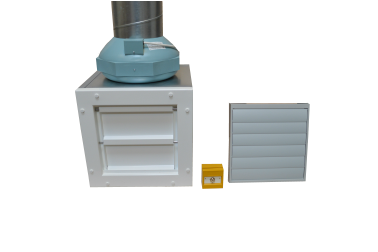

Combined Pressure Vent and Extraction Vent (Clean Chemical Systems only)

As with all Fire Suppression System installations if there is no natural venting to fresh air e.g. a door to fresh air within the room, then forced venting must be provided to ensure that after a fire and or discharge that any contaminants such as smoke or the Fire Suppression Agent itself can be extracted.

As with all Fire Suppression System installations if there is no natural venting to fresh air e.g. a door to fresh air within the room, then forced venting must be provided to ensure that after a fire and or discharge that any contaminants such as smoke or the Fire Suppression Agent itself can be extracted.

With Clean Chemical Agents such as FM200 and Novec 1230 the Extract Vent can be combined with the Pressure Vent so that only one system has to be installed, saving wall space and money. To extract a Clean Chemical Agent a floor box Extraction Vent is installed, as the agent is heavier than air and the Pressure Vent is fitted to the front of the box.

Special Vents and Accessories

Special built to order products are available such as insulated electrically operated external doors for freezer units and ceiling vents, please contact us if there is something you need that isn’t listed above.

Download Over Pressure Vents Brochure

Download FM200 Novec 1230 Extraction Brochure

Download Inert Gas Extraction System Brochure